The Engineering + Advanced Manufacturing Center of Excellence offers smart manufacturing training in automated labs that are changing the way we learn and live. This premier education center in Central Wisconsin features state-of-the-art spaces including an Industry 4.0 Smart Manufacturing Lab, Electronics, Mechanics + Robotics Lab and Mechatronics + Fluid Power Lab.

Advance your future with advanced technology in lights-out manufacturing, automation and AI.

Industry 4.0 Smart Manufacturing Lab

Lights Out Manufacturing System

Automation Systems Capstone Cell

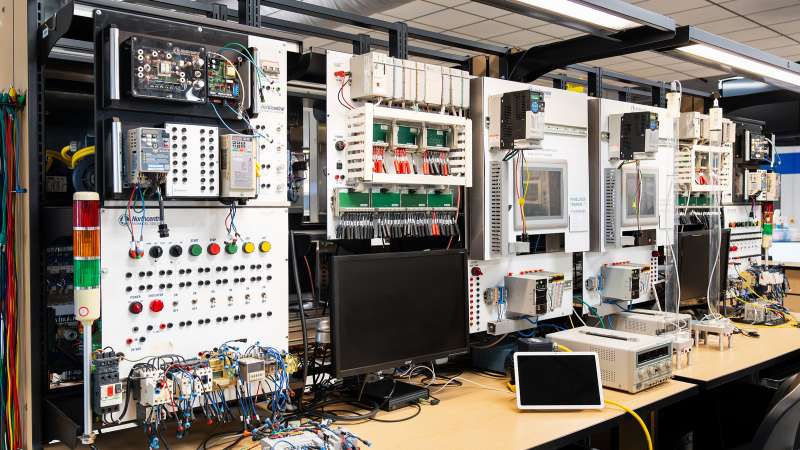

Electronics, Mechanics + Robotics Lab

Industrial Robots

Programmable Controllers

Mechatronics

Process Control

Electronics

Mechanical Systems

Mechatronics + Fluid Power Lab

Electromechanical Capstone Cell

Apprenticeship Lab Space

Fluid Power Technology

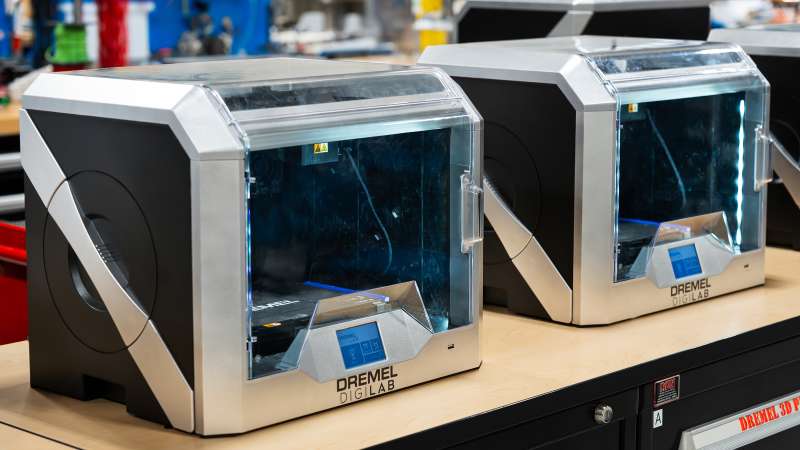

3D Printing

Programs Offered

The learning that takes place in the Engineering + Advanced Manufacturing Center of Excellence supports program students, apprentices and incumbent workers.

Hours + Contact Information

Hours

Monday, Wednesday, Thursday: 8:00 a.m. – 4:00 p.m.

Tuesday: 8:00 a.m. – 8:00 p.m.

Friday: 8:00 a.m. – 12:00 p.m.

Contact Information

For details about the technology in each of the labs, contact Dustin Van De Weerd, Program Director at vandeweerd@ntc.edu or 715.803.1247.