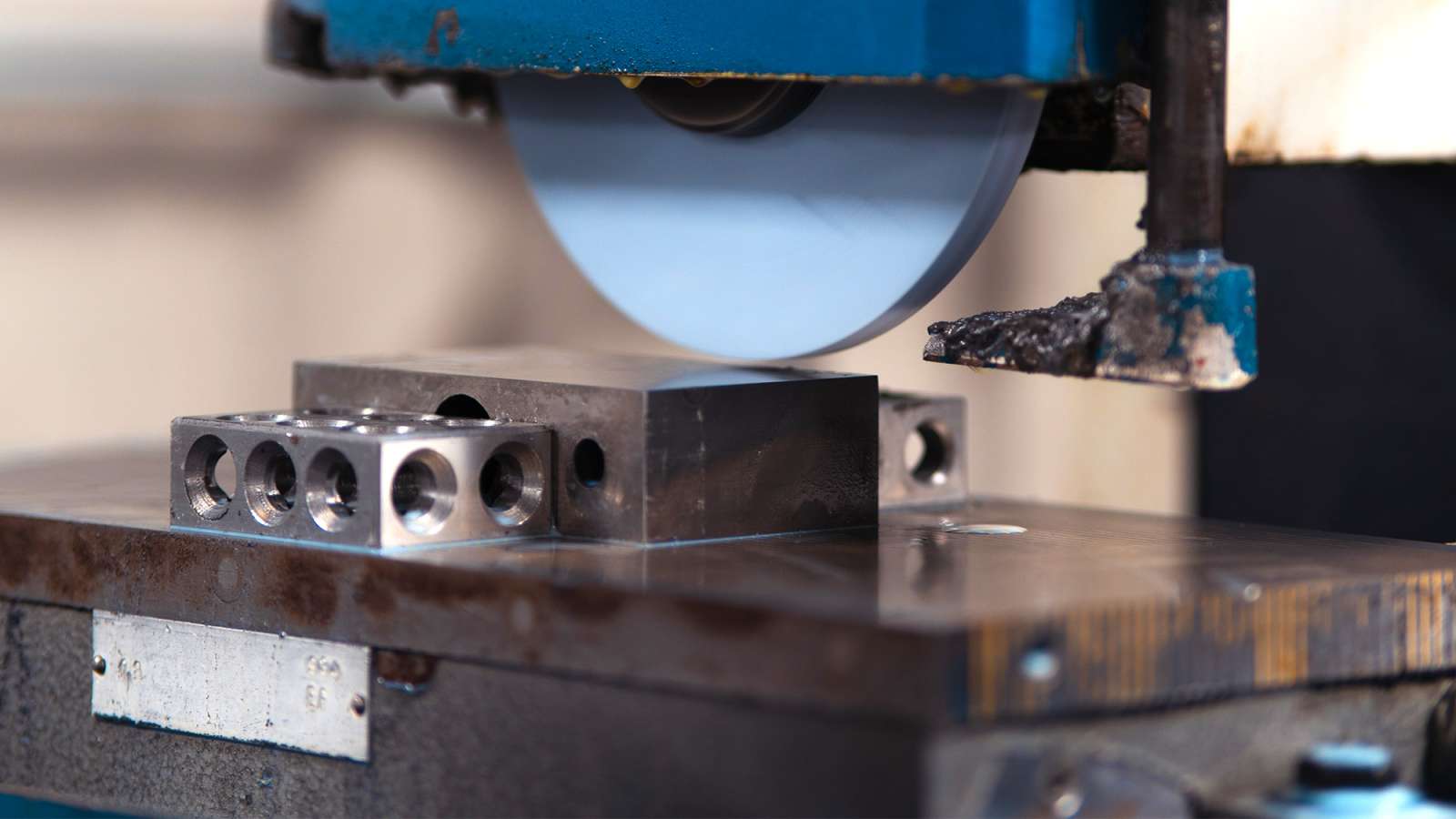

Tool and die makers analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, gauges, jigs, fixtures (devices that hold metal while it is shaped, stamped or drilled), gauges and machinist’s hand tools.

Die makers construct metal forms (dies) to shape metal in stamping and forging operations. A tool and die maker operates various machine tools to make and repair molds, special machinery, tools, dies, jigs, fixtures and die cast dies.

In this apprenticeship, learn basic theory in machining, blueprint reading and metallurgy, in addition to knowledge in stamping, mold making blanking, jigs and fixtures, plastics and die casting. Computer-assisted CNC machining and die and mold design are also covered.

Terms of Apprenticeship

- 5-year training program

- 9,888 hours on-the-job training

- 576 hours paid related instruction

- Apprentice must complete the Transition-To-Trainer Course in final year of apprenticeship

2024–25 Curriculum

Get Started

To apply for an Apprenticeship, you must be employed by a business or organization that participates in an apprenticeship program and has a completed Department of Workforce Development (DWD) contract. Each employer sets its own requirements for entry into the program. To determine your eligibility and explore available opportunities, contact your employer’s human resources department.

Questions?

If you have questions about this apprenticeship or the application process, please contact our Recruitment team.