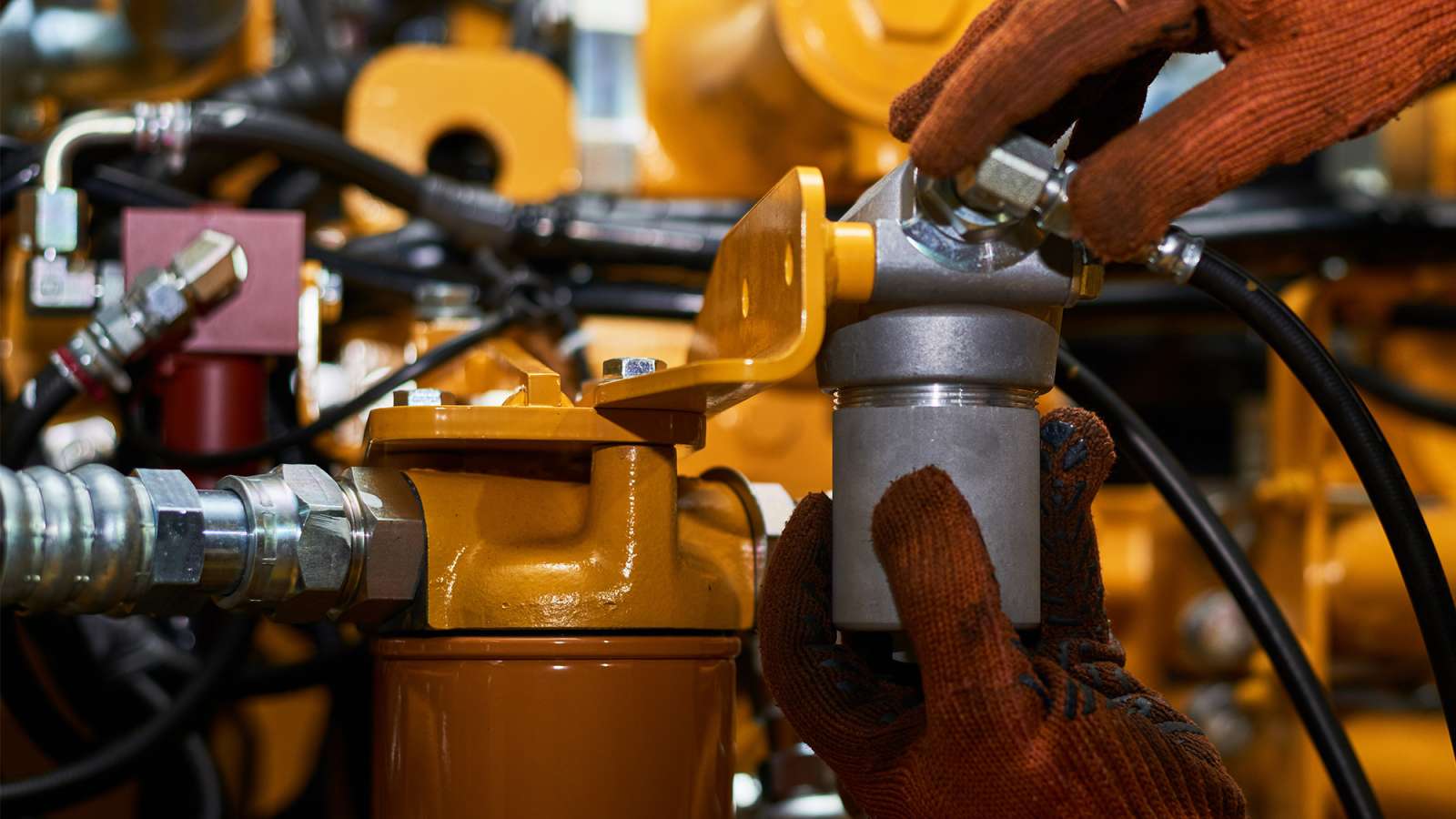

Lubrication Technician apprentices work with industrial machinery and equipment components to apply lubricants required to proper operation.

Apprentices will learn to adhere to safety and industry standards and demonstrate safe work practices. In related instruction, apprentices will learn to compare greases, oils, hydraulic fluids and other lubricants; perform general lubrication, operate hydraulic and central lube oil systems; and perform preventative maintenance.

Terms of Apprenticeship

- 2-year program

- 3,712 hours of on-the-job training

- 360 hours of paid related classroom instruction

- Transition-To-Trainer Course in the final year of the apprenticeship

2024–25 Curriculum

Get Started

To apply for an Apprenticeship, you must be employed by a business or organization that participates in an apprenticeship program and has a completed Department of Workforce Development (DWD) contract. Each employer sets its own requirements for entry into the program. To determine your eligibility and explore available opportunities, contact your employer’s human resources department.

Questions?

If you have questions about this apprenticeship or the application process, please contact our Recruitment team.