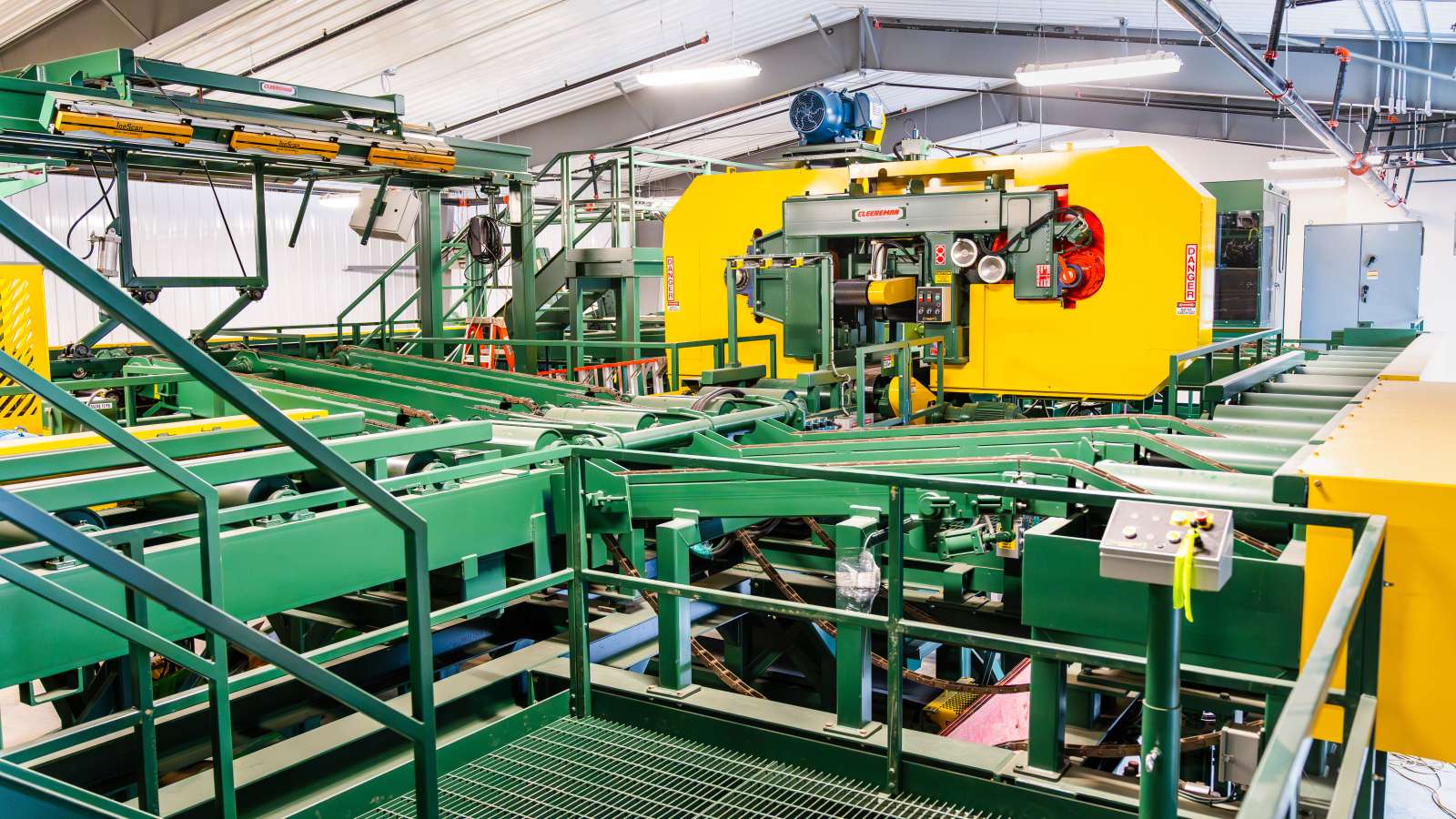

The NTC Sawmill is a state-of-the-art modern lumber manufacturing facility, created to help train students in the latest technologies, safety practices and career skills in the lumber industry. The NTC Sawmill is the only commercial scale training sawmill in the United States.

All of the equipment in the facility is elevated to improve access for maintenance and space for teaching. As a training lab, the focus is on learning about the lumber industry and its best practices. While learners operate top of the line commercial scale equipment, the focus is always about safety and learning best practices.

A One-Of-A-Kind Facility

This one-of-a-kind facility allows students the opportunity to experience the industry that feeds raw material for furniture, cabinets, windows, doors, flooring, trim, pallets and countless other wood products people use every day.

Lumber Processing

Head Saw

Resaw

Optimized Edger

Scanner

Training Offered

Programs and courses that utilize the Sawmill provide students with hands-on training and practical skills, preparing them for careers in the wood manufacturing industry.